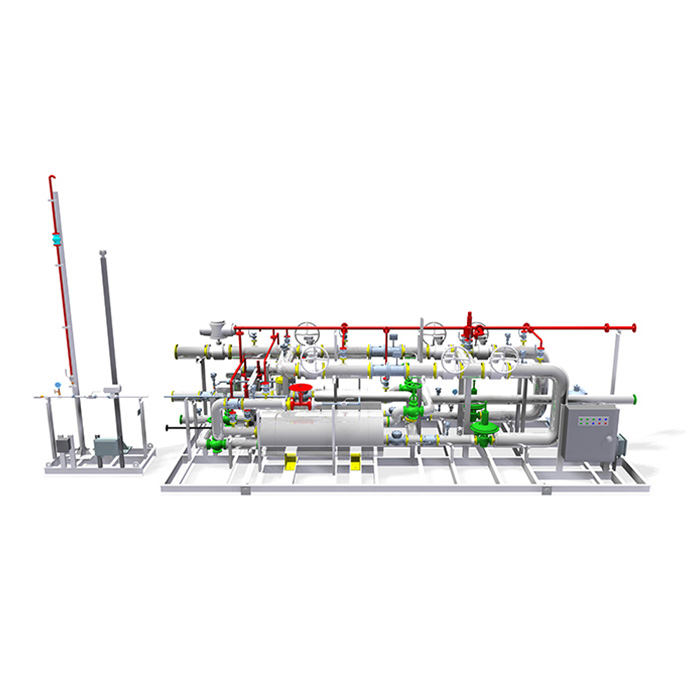

CNG Decompression Skid

Non-standard design with flexible and variable configuration options, customizable based on user's gas consumption requirements. Multi-port design ensures safe storage and transportation. Flexible gas storage capacity reduces user investment costs. Lightweight design compatible with various truck types for transport. Aesthetically pleasing with unique rainproof design. Cylinder manifold rack is an advanced, high-tech gas filling and manifold device. It features simple operation and convenient transportation, suitable for industrial enterprises with high consumption of bottled gases. Available in vertical and horizontal configurations. Maximum Working Pressure: 20 MPa. Strength Test Pressure: 30 MPa. With the rapid development of natural gas exploration and utilization in China, Compressed Natural Gas (CNG) is produced by purifying and compressing wellhead or pipeline gas, followed by high-pressure storage and transportation. First, the CNG transport trailer delivers the compressed gas skid to the supply station. The high-pressure hose from the unloading post is connected to the CNG Pressure Reduction Skid. Upon entering the skid, the gas passes through a filter. The gas is then heated by a heat exchanger and regulated to 1.6 MPa by the primary pressure regulator. It then flows to the secondary regulator to achieve the required pressure. During heat exchange and pressure regulation, the system includes low-temperature protection for natural gas, overpressure protection at primary outlet (overpressure cut-off and venting), and overpressure protection downstream of the relief device (overpressure cut-off and venting). After pressure regulation by the CNG Pressure Reduction Skid, the gas is metered, odorized, and fed into the gas pipeline network.

网安备案

网安备案