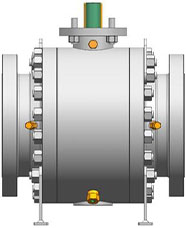

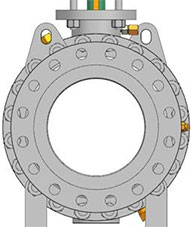

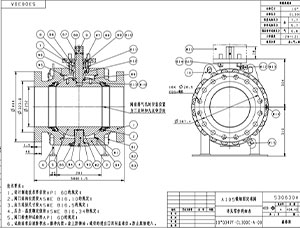

We use professional German modeling software for 3D modeling and 2D engineering drawing creation, thus ensuring high efficiency and precision.

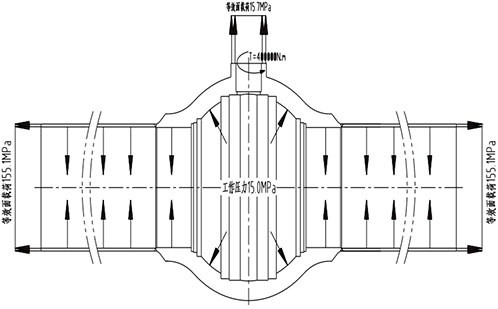

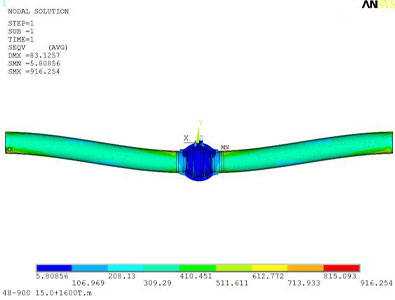

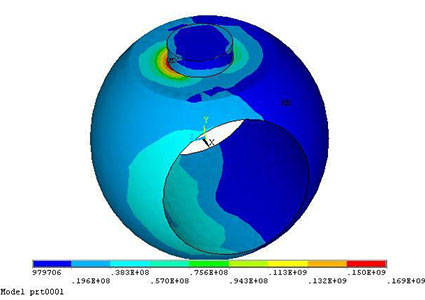

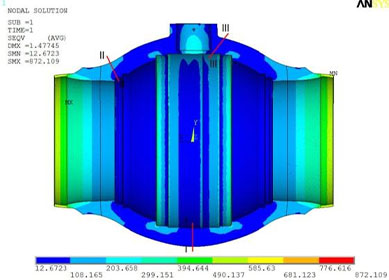

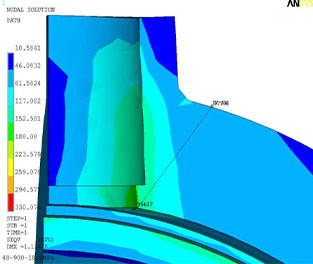

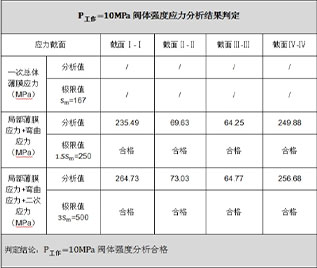

We use professional American engineering simulation software for strength analysis of pressure-bearing parts to verify and optimize their structure and wall thickness

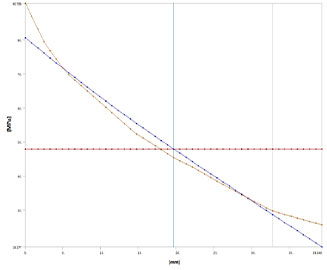

We use professional American engineering simulation software to perform stress linearization analysis on pressure-bearing components and categorize stress types for more precise and economical results, thereby avoiding over-engineering

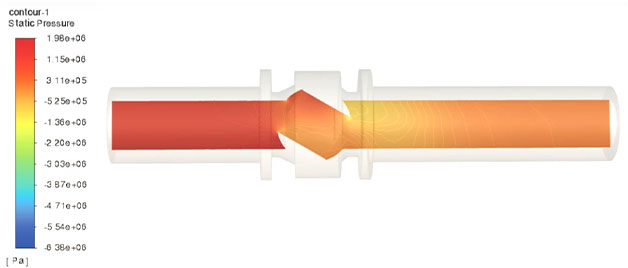

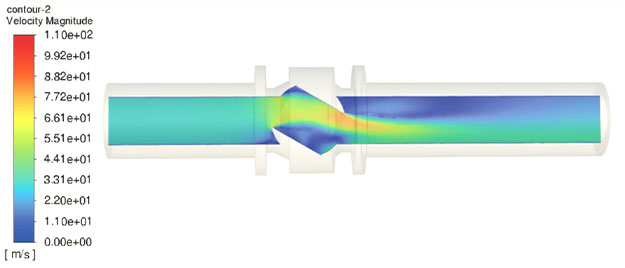

We use professional American fluid simulation software for flow path analysis to optimize the flow channel design.

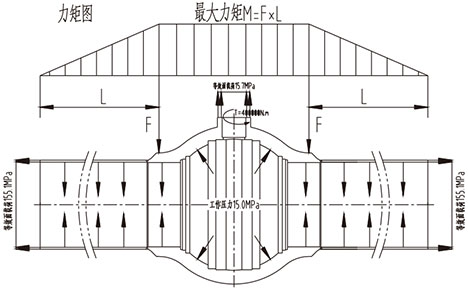

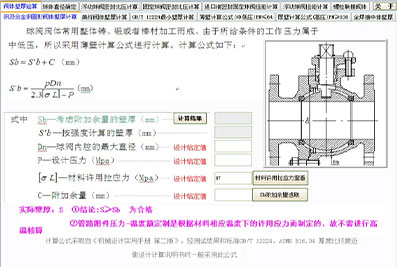

We utilize specialized valve design software to perform calculations for wall thickness, ball diameter, specific sealing pressure, torque, and other critical parameters.

With the aid of professional calculation software, design is no longer guided solely by empirical experience; instead, we conduct indepth research into product mechanics, making the design process more efficient and rational.

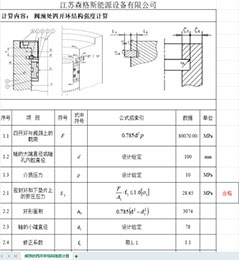

Valve design verification spreadsheets are compiled based on relevant valve design manuals and standards to assist designers and ensure product quality.

网安备案

网安备案